Understanding Tattoo Pigments

Tattoo pigments are the core ingredients that give tattoo ink its vibrant color, saturation, and longevity. These pigments are finely ground particles suspended in a carrier solution to ensure smooth application into the skin. The type of pigment used directly affects a tattoo's brightness, stability, and healing process. With increasing global regulations, particularly REACH compliance in the European Union, tattoo manufacturers must reformulate and test pigments to meet strict safety standards.

- Derived from carbon-based molecules, organic pigments are known for their vibrant colors and high saturation.

- They provide some brightest and boldest tattoo colors, commonly used in reds, blues, yellows, and greens.

- While synthetic organic pigments are lab-engineered for better stability and reduced skin reactions, older formulations have historically contained potentially harmful azo dyes, which are now restricted under REACH regulations.

REACH Compliance Note: Many older organic pigments, particularly certain reds and yellows, were flagged due to concerns about carcinogenic aromatic amines released as they break down in the body. Modern REACH-compliant inks replace these restricted pigments with safer alternatives while maintaining vibrancy.

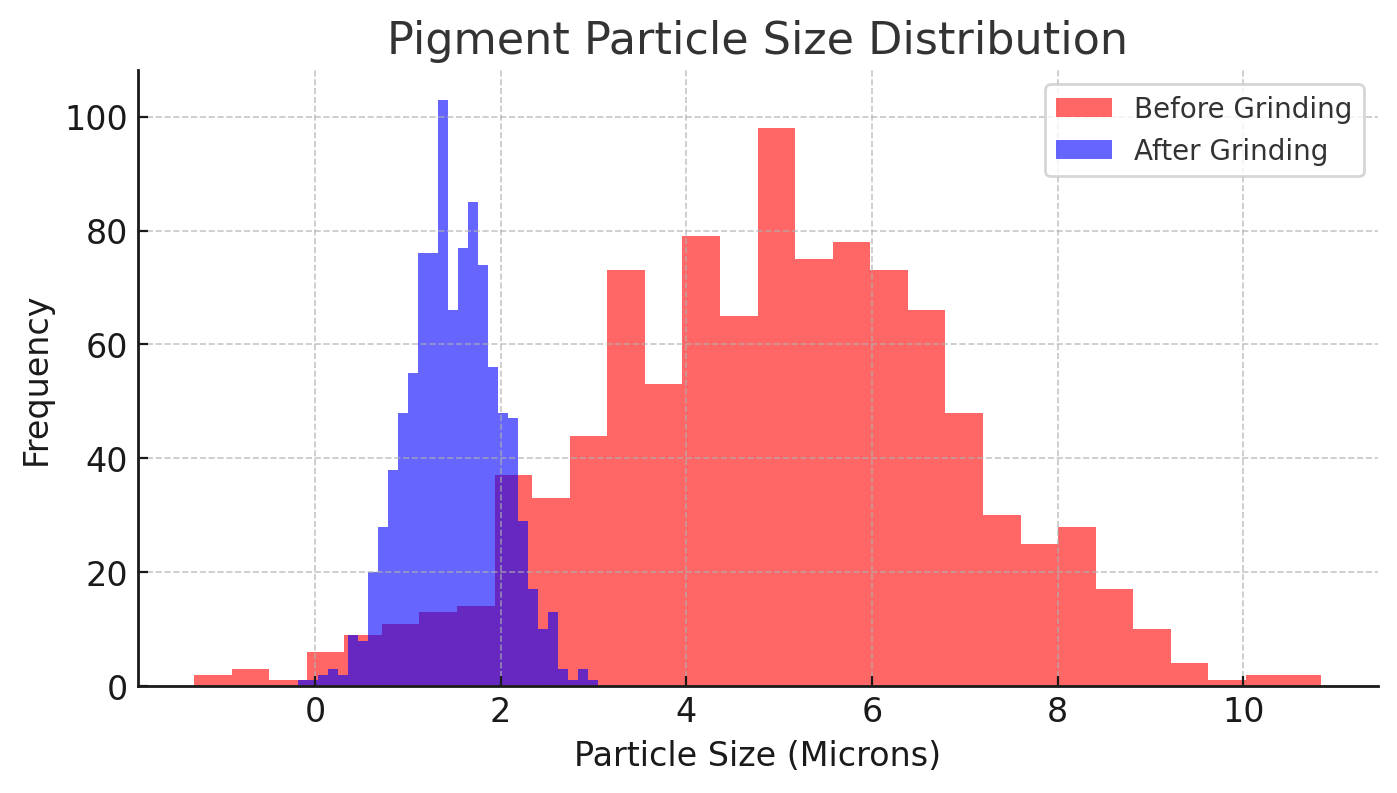

Pigment Particle Size Distribution

Smooth Application: Fine, evenly ground pigments allow for better flow through the tattoo needle, reducing clogs and ensuring consistent ink placement in the skin.

Better Color Saturation: Properly sized pigment particles distribute evenly, creating bold, vibrant tattoos that heal cleanly.

Long-Term Stability: Uniform pigment size prevents ink migration and fading, keeping tattoos looking fresh for years.

Safer for the Skin: Large, irregular particles can irritate, while properly ground pigments reduce the risk of allergic reactions.

Graph Information

The diagram visually represents the difference between unrefined and perfectly ground pigment particles, demonstrating how precision grinding enhances ink performance.

Preservatives – Keeping Ink Fresh (But Not Always Safe)

What They Do:

- Prevent bacteria, mold, and fungi from growing in tattoo ink.

- Extend the ink’s shelf life so it doesn’t spoil before use.

Why Some Can Be Harmful:

- Some cheap or harsh chemical preservatives (like formaldehyde-releasing agents) can cause skin irritation, allergic reactions, or long-term health risks.

- Parabens and certain alcohol-based preservatives can make the ink too harsh for the skin, leading to poor healing or fading tattoos.

Safer Alternatives:

Look for inks that use gentle, skin-safe preservatives tested for tattoo applications. REACH-compliant tattoo inks ensure that only non-toxic preservatives are used.

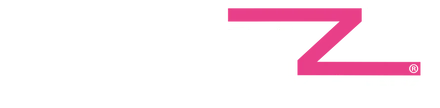

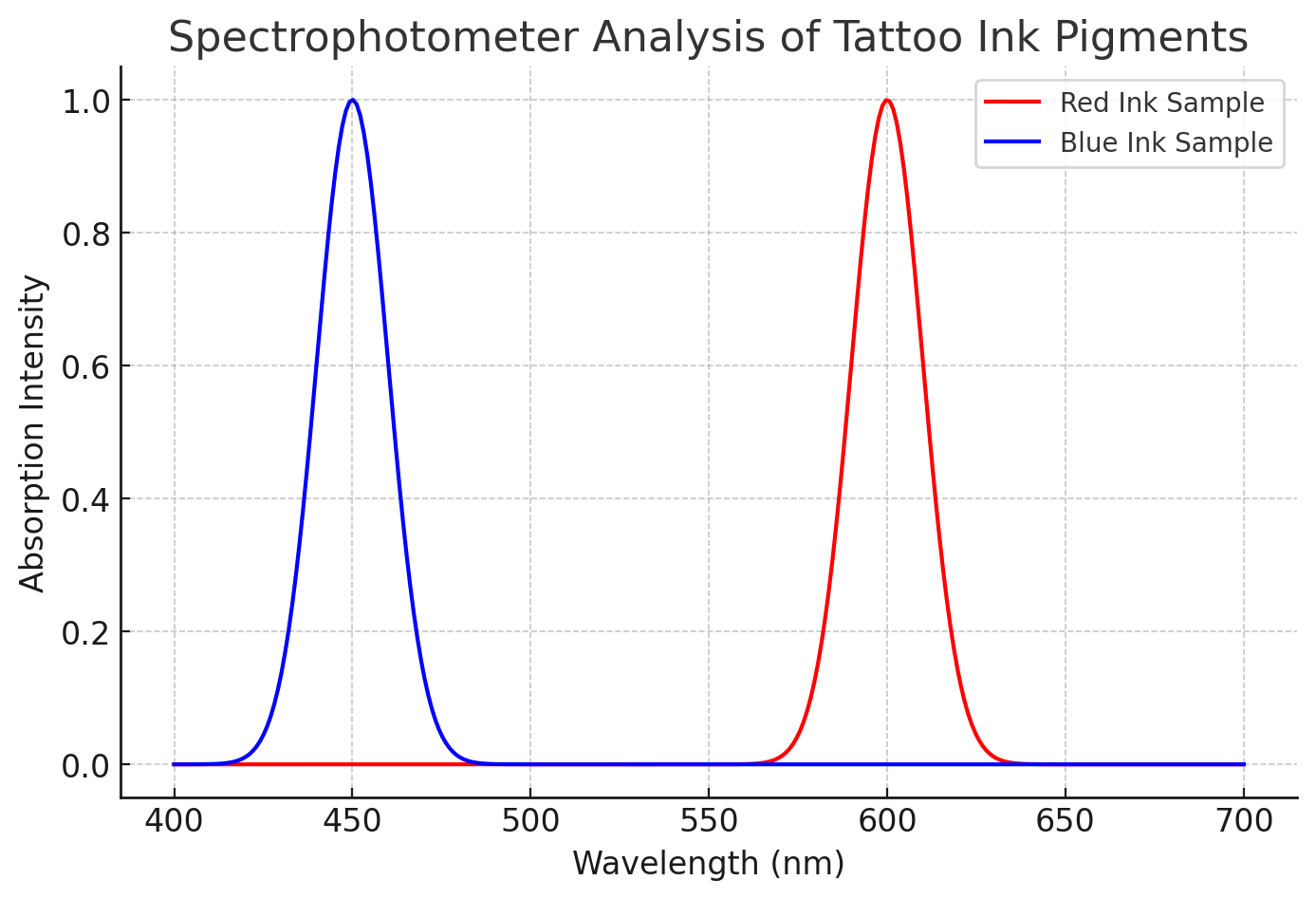

What is a Photo Spectrometer?

- Tattoo artists require perfectly matched ink colors for consistency, especially for multi-session tattoos or color touch-ups.

- The spectrometer scans ink samples before bottling to verify that the color matches the intended shade.

- If discrepancies are found, adjustments are made to maintain batch-to-batch consistency.

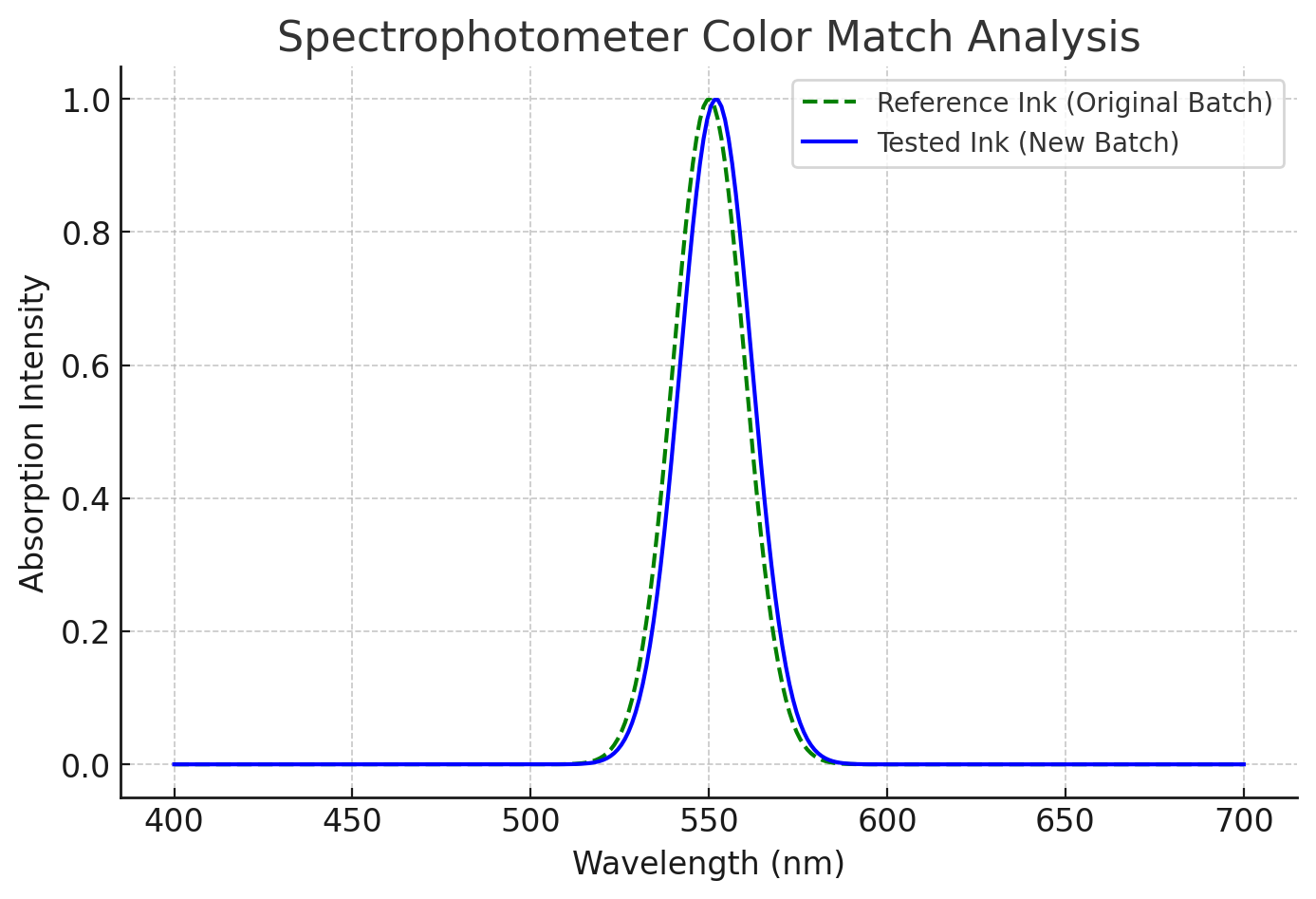

The Importance of Proper Water Use and pH Levels in Tattoo Ink

- Purity and Sterility – Any water used in tattoo ink must be ultra-purified, sterilized, and free from contaminants, including bacteria, heavy metals, and organic impurities.

- Prevents Contamination and Microbial Growth—When tattooed into the skin, Impure water can introduce bacteria, mold, or fungi, leading to infections.

- Ensures Ink Flow and Stability—High-quality deionized (DI) or distilled water helps maintain a smooth, even ink consistency, preventing needle clogging and uneven application.

Consistency in Color Suspension:

Poor-quality water may cause pigment particles to separate or settle improperly, resulting in patchy healing or fading over time.

At INTENZE, only ultra-purified water is used, ensuring absolute sterility and performance.

Why a C.I. Number Alone Does Not Determine Tattoo Pigment Safety

A pigment with the same C.I. Number can exist in different grades (industrial, cosmetic, or medical).

Industrial-grade pigments may contain impurities like heavy metals, carcinogens, or solvents, making them unsafe for tattooing.

Only high-purity, cosmetic, or medical-grade pigments are safe for human skin.

How to Properly Store Tattoo Ink and Why It Matters

Keep Ink in a Cool, Dry Place

- Ideal Temperature: Store tattoo ink between 50°F - 75°F (10°C - 24°C).

- Why? Extreme heat can break down pigments and cause Ink to separate, while cold temperatures can thicken or crystalize it, making it challenging to work with.

- Avoid Storing Ink near radiators, direct sunlight, or freezing environments.

Shop Now

- Choosing a selection results in a full page refresh.

- Opens in a new window.